Our solutions

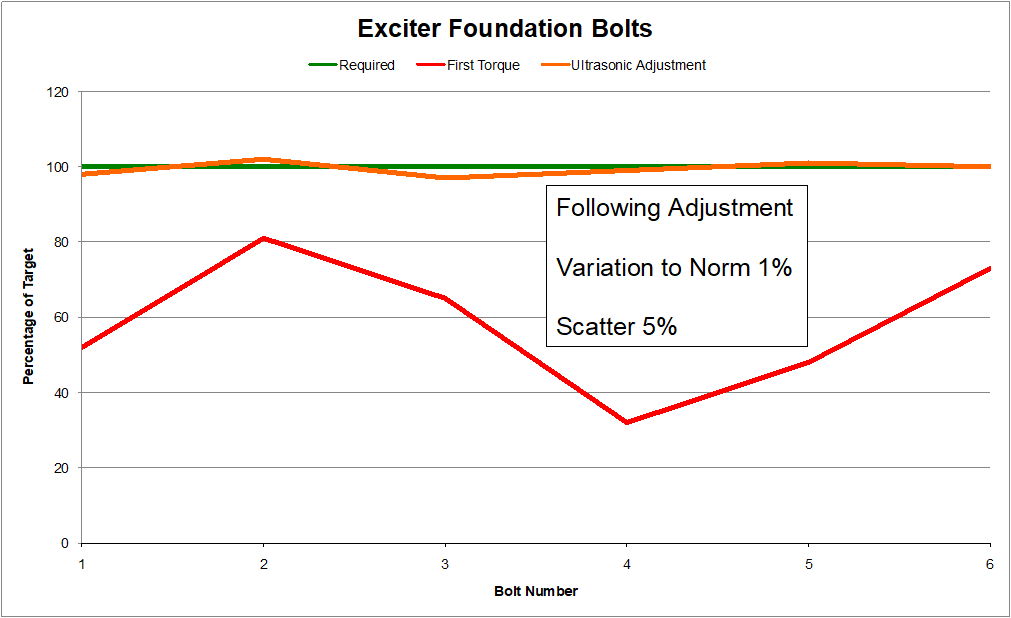

We use Ultrasonic bolt tension measurements too prove the achieved pre-load and then adjust the torque settings until the Tension meets the OEM specification.

The process we follow is:

Preparation – prior to work start

-

Calculate allowable tension for the Bolts

-

Determine allowable stresses for mating parts

-

Review the OEM requirements

-

Set up ultrasonic data files

-

Measure ultrasonic bolt reference lengths

During re-assembly

Apply the torque wrench whilst simultaneously measuring the residual tension STOP when the ideal tension is reached to ELIMINATE THE TORQUE VARIABLES.

Final Results

Summary

This solution eliminated the failure of these bolts and allowed the mine to keep running between major planned shutdowns. This improved both productivity and safety. If you wish to know more please feel free to call or email us at:

Mobile: Trevor Robinson 0411 132784

Email: trevor.robinson@norbar.com.au