Why do heat exchanger gaskets leaks so frequently? View our video to find out, or read on!

Well, part of the answer lies in the opening statement. The gaskets leak because the assembly of the joint is not as good as most people believe.

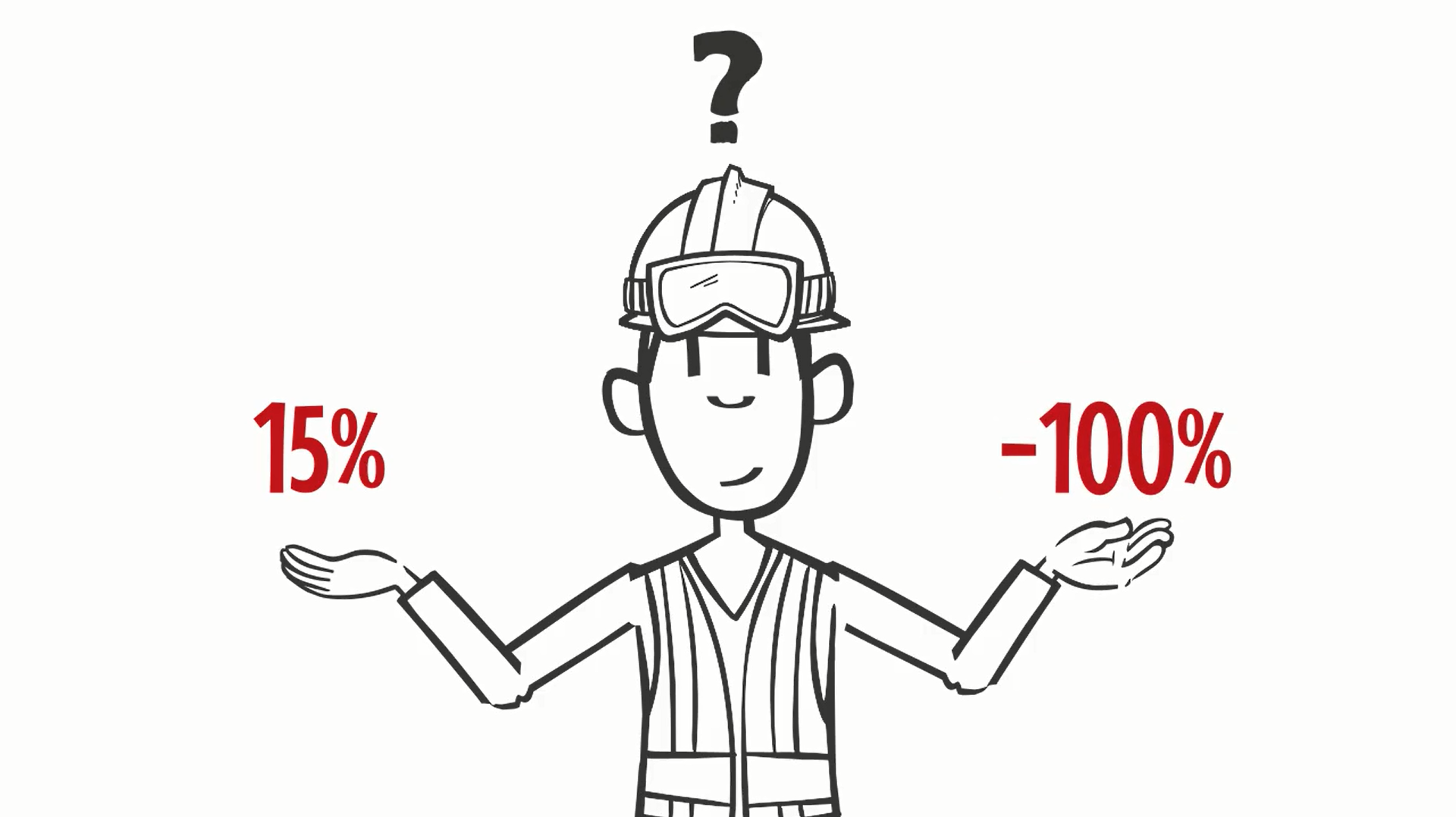

There is a common assumption that using a controlled torque process ensures that the bolts have the correct tension. Well put quite simply, it doesn't! The variation is +15% to -100%.

How do we know this? I'll explain. Even with the best controls in place…

…it is very unlikely that the bolt tension will be evenly distributed around the joint. And that is why joints leak.

The solutions we provide and that have a 27 year long 100% success rate ensure that each bolt has the correct bolt stress or tension.

We use a five step process.

-

Our first step is to confirm the optimum bolt tension using our flange management software

-

Step two: Using our sixth-generation ultrasonic bolt stress measurement technology. We measure each bolt prior to installation.

-

Step three: We tighten each bolt using the approved techniques.

-

Step four: We measure every bolt and review the results.

-

Step five: We adjust all those that are significantly below the target. In most cases, once we've adjusted those lows, the highs relax and we get a nice even bolt tension.

The result is a leak free joint at startup and no loss of containment during operation!

I hope that this has been of interest to you. If you have any bolting procedures that you would like to improve, please contact us or call us on +61 411 132 784