Most mill operators are familiar with (and regularly go through) a process known as re-torque.

Re-torque is an expensive exercise resulting in lost production, but is believed to be necessary in order to avoid bolt failures that cause unplanned shutdowns.

It doesn't have to be this way however, by eliminating the root cause of the failures we can eliminate the need for re-torque all together.

Costly Bolt Failures

Many Mills experience liner and liner bolt failures. These failures are costly and can affect the viability of some operations.

Boltstress Ultrasonics has eliminated these at several mine sites and mills.

Liner bolts fail (break or loosen off) for a number of reasons but the vast majority of these can be eliminated if the pre-load is correct. Fatigue failure is the most common mode; this is almost invariably due to pre-load that is too low. This can in turn be divided into 3 groups: inadequate original tension, consistency and high relaxation.

Pre-load Too Low

The interfaces between the bolt, liner & shell are rarely in a smooth or machined condition, consequently the friction is greater than standard calculations consider. This results in low average bolt tension.

Bolt Tension Consistency

Consistency of Bolt Tension is a bigger factor than most realize. The relationship between torque tightening and bolt tension in good conditions is generally regarded as +/- 25%.

Add in rough surfaces, interaction and short clamp length to diameter ratios and this becomes significantly worse.

Our experience demonstrates that the variation becomes more like +25% – 100%; it is rare when we measure all bolts that we don't find at least one that is completely loose.

High Relaxation

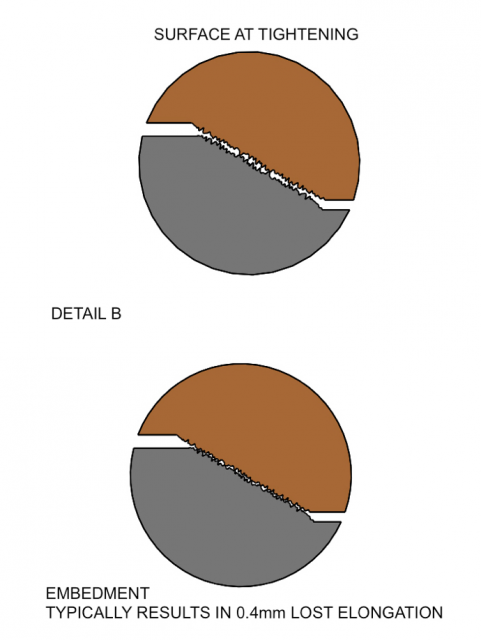

The relaxation on liners is particularly high, the mating surfaces between the lifters, liner bolts and liner plates are roughcast and tapered. Any small embedment of high spots will be multiplied by the slope angle.

By way of an example, if 0.1mm embedment occurs on a 1:4 taper that will result in 0.4mm in lost elongation. That is a likely scenario when both sides of the slope are considered.