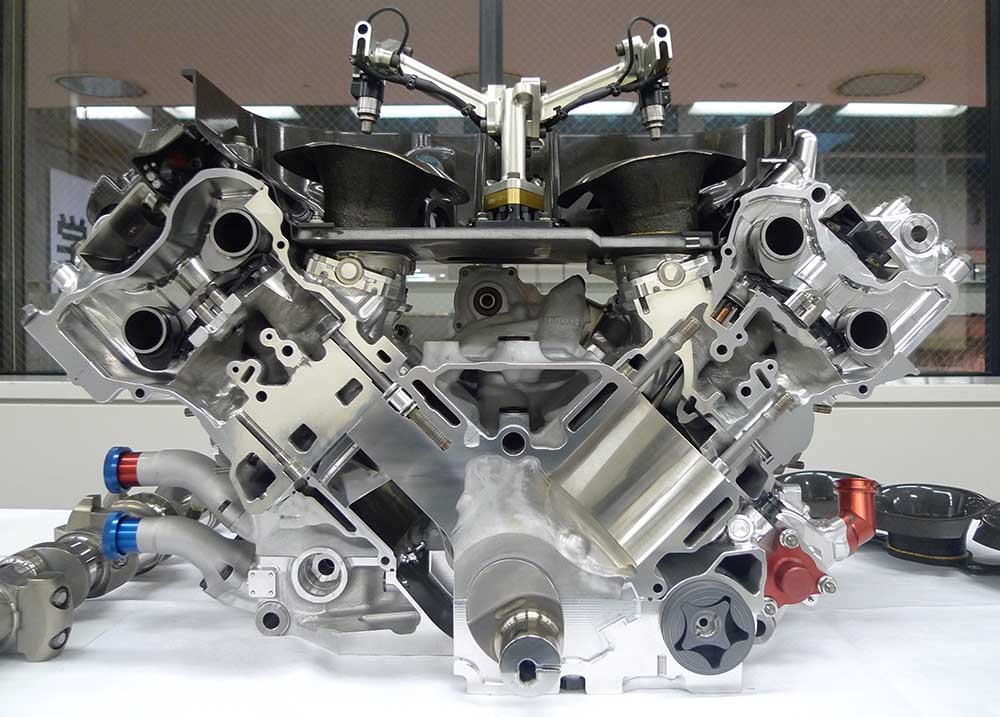

F1 Racing Engines

We have helped racing teams prevent engine failure caused by con rod and cylinder head breaking. In 1996 we eliminated a con-rod failure for a Formula One racing team using ultrasonic bolt stress measurement. In subsequent years we have provided solutions to many industrial, marine and commercial engine assemblers.

The applications include:

Crushers

Mine site crushers have an extremely arduous life cycle. Many bolt fail or loosen in service and many operators regularly have to re-tighten bolts.

We provide 3 solutions: Ultrasonic Bolt Tension Verification, optimum tightening tooling & our on line tension retaining system, Energizer.

Energizer stores energy that increases the reliability of joint assemblies, whenever parts embed causing relaxation the stored compressed energy keeps the tension in the bolts, preventing break downs.

Heat Exchanger & Pressure Vessel Solutions

Refineries, Oil Rigs, FPSO's, Power Stations and many other plants use Heat Exchangers as part of their process. These have many joint failure modes, we solve all of them but the most common are the girth joints on the heads, channels and tube sheets.

Background, the various design codes all engineers to tailor these flanges to suit the vessel dimensions. As these flanges are often individually forged they are one of the more expensive items, consequently designers seek to minimize both the thickness and diameter. This is all fine in theory but the result is normally many small bolts instead of fewer larger ones.

This page explains the challenges and solutions we provide.